MANAGEMENT SYSTEMS

- Quality System according to ISO 9001 since 1994

- Quality Management System according to ISO TS 16949 (now IATF 16949) since 2011

- Environmental Management System Certificate according to ISO 14001 since 2003

- Occupational Safety and Health Management System according to OHSAS 18001 since 2009

- Certification of QMS by TÜV SÜD

- Certification of EMS and HSMS by DNV GL

- Approved products by certification companies them TÜV SÜD, TÜV Rheinland, Bureau Veritas, DNV-GL, LR, Arrowhead, HSB, SII, RMR, SVTI, DOT, TC, etc.

NORMS AND STANDARDS

- European Standards (EN ISO 9809-1,2, EN 1964-3, PED, TPED)

- International Standards (ISO 9809-1,2, ISO 11120, ISO 11439, UN ISO 9809-1)

- American Standards (DOT 3AA, ASME CODE section VIII, div. 1)

- Canadian Standards (TC - 3AAM)

- British Standards (BS 5045)

- Regulations (AD 2000, ADR/RID, IMDG, ECE R 110)

- Eurasian Economic Union – acc. TP TC 032/2013, TP TS 018/2011

- India – acc. Gas Cylinder Rules 2016 and Gas Cylinder Rules 2004

- Australia – acc. Occupational Health and Safety Regulation

SPECIAL NON-DESTRUCTIVE TESTING

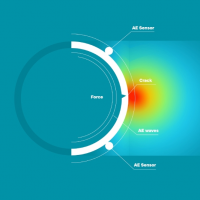

The Cylinders Holding group has a unique non-destructive testing technology (so-called acoustic emission), which can be used not only for testing Cylinders Holding’s products and its applications, but also for other pressure systems (pressure pipeline, pressure fittings, boilers, etc.). This method is unique due to the range of tested pressure levels and mobility, which guarantees the possibility of testing anywhere in the world in a short period of time.

CONTROL PROCEDURE

Our manufacturing process undergoes strict quality control from the beginning to the end. The control procedure of production process is based on various kinds of non-destructive testing procedures that are carried out within different stages of the production flow. The achievement of required mechanical properties is tested on 100 % products by hardness testing and finally by an independent laboratory. After successful final inspection the appropriate certificates are issued for each product and order. The quality of products and order documentation are verified by an independent notified body.

SERVICES

The experienced team of experts in the Cylinders Holding group is able to implement various types of pressure components testing in terms of non-destructive tests, pressure tests up to the pressure of 2000 bar and fatigue tests.