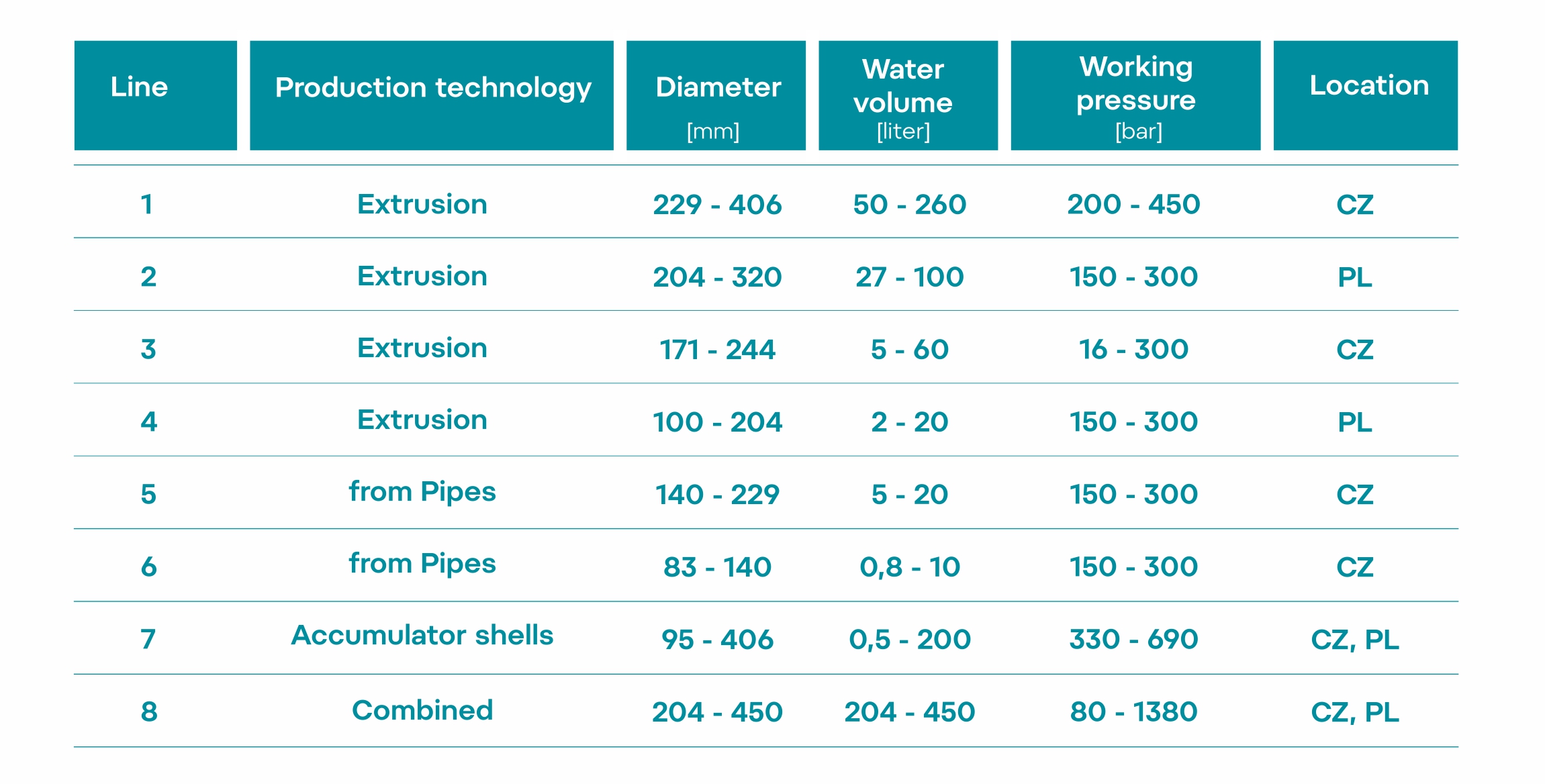

Cylinders Holding uses 8 production lines which cover the wide production portfolio of cylinders, tanks, pressure vessels, H2 storage vessels and accumulator shells, as shown in the table below.

Manufacturing companies of the Cylinders Holding Group have a number of unique technologies, primarily of special production methods of seamless high-pressure steel cylinders, tanks, accumulator shells and pressure vessels made from billet by the reversed extrusion method.

Another unique methods for the production of these mentioned products are unique “tailor made” technologies:

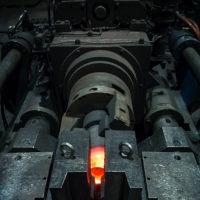

- Rotary die forming

- Rotary forging

- Spinning forming

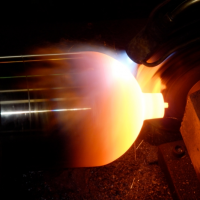

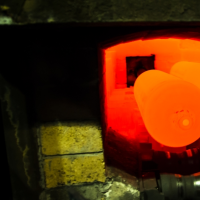

From the point of view of heat treatment, Cylinders Holding Group operates a number of furnaces in which can be processed a wide range of all products and material grades.

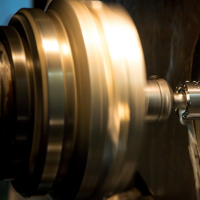

During our production processes, we also use a number of special CNC turning and milling centers made especially for processing all the range of products of Cylinders Holding.

An integral part of the production capacities are also unusual special devices for destructive and

non-destructive testing of all manufactured products. These devices include pressure testing chambers up to 1600 bar, destruction testing rooms up to 2000 bar and the largest test facility in the world for volumetric expansion testing (Water Jacket) with a test pressure up to 720 bar.

We are also outstanding in the field of the most advanced technologies for the application of anticorrosive surface protection and cleaning of the inner surface of cylinders and tanks fulfilling the most demanding requirements of the automotive and gas industry.